High Performance Light Stabilizer DB886

Characterization

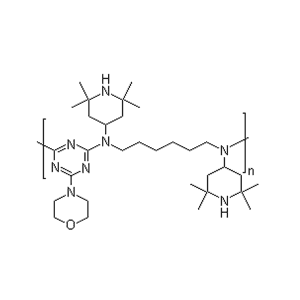

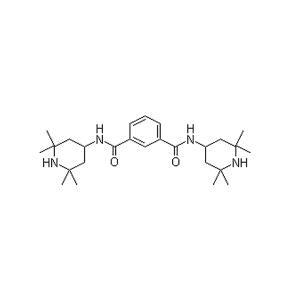

DB 886 is a high performance UV stabilization package designed

for polyurethane systems (e. g. TPU, CASE, RIM flexible foam applications).

DB 866 is particularly efficient in thermoplastic polyurethane (TPU). DB 866 can also be used in polyurethane coatings on tarpaulin and flooring as well as in synthetic leather.

Applications

DB 886 provides outstanding UV stability to polyurethane systems.

The increased effectiveness over conventional UV stabilizer systems is particularly pronounced in transparent or light colored TPU applications.

DB 886 can also be used in other polymers such as polyamides and other engineering plastics including aliphatic polyketone, styrene homo- and copolymers, elastomers, TPE, TPV and epoxies as well as polyolefins and other organic substrates.

Features/benefits

DB 886 offers superior performance and increased productivity

over conventional light stabilization systems:

Excellent initial color

Superior color retention during UV exposure

Enhanced long-term–thermal-stability

Single-additive solution

Easy dosable

Product forms White to slightly yellow, free-flowing powder

Guidelines for use

Use levels for DB 886 typically range between 0.1 % and 2.0 %

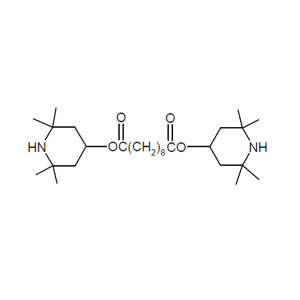

depending on substrate and processing conditions. DB 866 can be used alone or in combination with other functional additives such as antioxidants (hindered phenols, phosphites) and HALS light stabilizers, where often a synergistic performance is observed. Performance data of DB 886 are available for various applications

Physical Properties

Solubility (25 °C): g/100 g solution

Acetone: 7.5

Ethyl Acetate: 9

Methanol: < 0.01

Methylene Chloride: 29

Toluene: 13

Volatility (TGA, heating rate 20 °C/min in air) Weight

loss %: 1.0, 5.0, 10.0

Temperature °C: 215, 255, 270